Innovation

DNA: INNOVATION + SUSTAINABILITY

“Innovation, which has always been a key value for our company, now takes on a new face, putting it at the service of sustainability.”

Innovation

DNA: INNOVATION + SUSTAINABILITY

“Innovation, which has always been a key value for our company, now takes on a new face, putting it at the service of sustainability.”

R&D&I MANIFESTO

2.

Before acquiring technology, we carry out research studies to obtain objective criteria and invest only in the one that best suits our requirements.

3.

We have developed our own rigorous criteria that guide us in our way of working and we are not guided by market trends.

4.

We have developed our own protocols, stricter and more demanding than those required by ISO, Systecode or other regulations.

5.

We have a laboratory team made up of two chemistry graduates, laboratory technicians, production staff and interns.

6.

30% of our team is trained to be able to detect low levels of TCA and other sensory deviations through sniffing technology with manual detection.

R&D&I MANIFESTO

2.

Before acquiring technology, we carry out research studies to obtain objective criteria and invest only in the one that best suits our requirements.

3.

We have developed our own rigorous criteria that guide us in our way of working and we are not guided by market trends.

4.

We have developed our own protocols, stricter and more demanding than those required by ISO, Systecode or other regulations.

5.

We have a laboratory team made up of two chemistry graduates, laboratory technicians, production staff and interns.

6.

30% of our team is trained to be able to detect low levels of TCA and other sensory deviations through sniffing technology with manual detection.

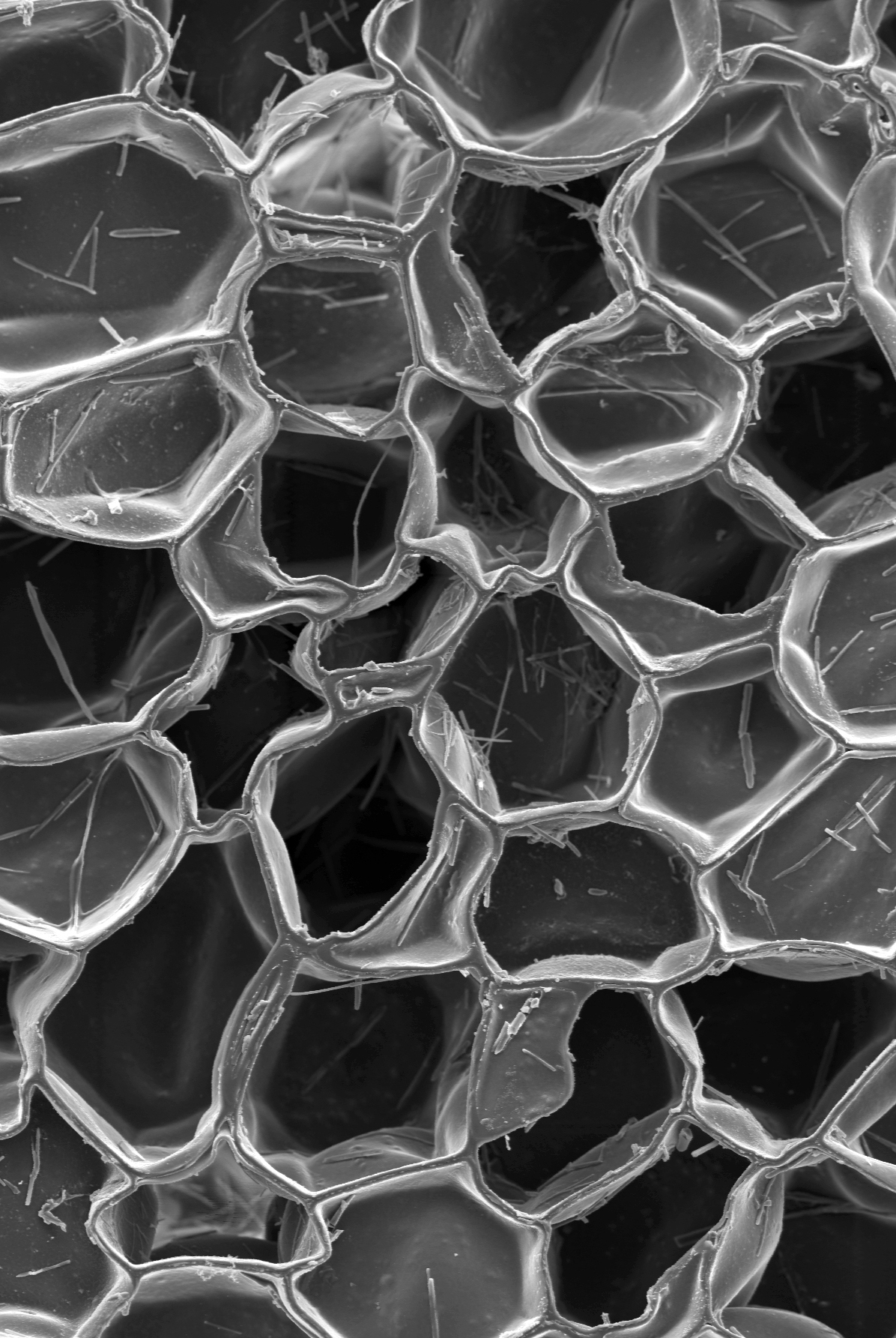

Microscopic image of a J·Vigas cork stopper.

Acknowledgments: Catalan Cork Institute

We were the first cork industry to bet on its own laboratory in 1985. Furthermore, during Enric Vigas’ stage as president of the Catalan cork association, the Catalan Cork Institute was founded, a research and innovation center based in Palafrugell.

We are convinced that innovation and knowledge are the basis on which to build construir our future, just as previous generations have done.

Our laboratory team is made up of Raquel de Nadal, Director of Sustainability and Innovation, a graduate in chemistry and currently preparing her PhD with research to eradicate TCA, a chemist, a production person and student interns.

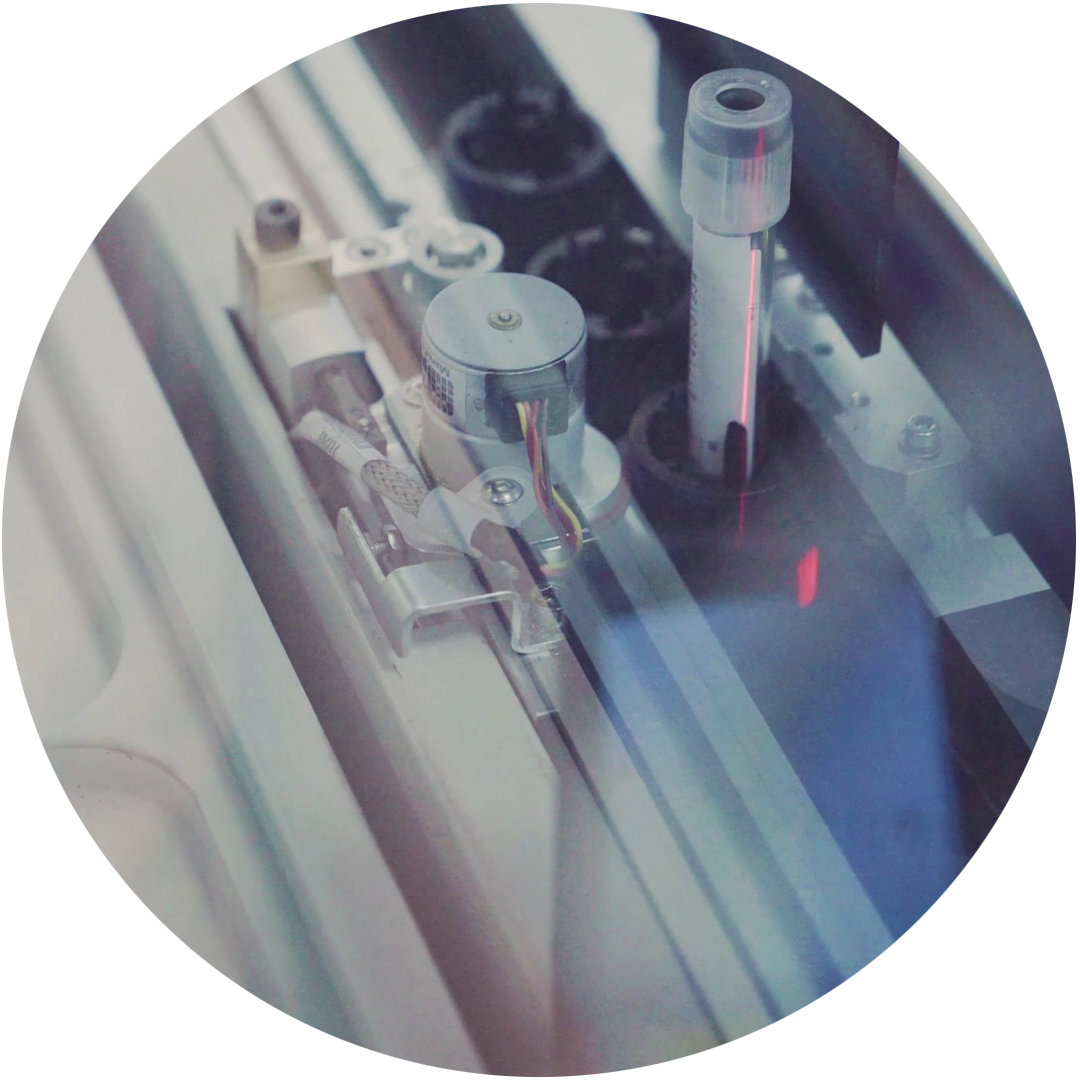

Among the laboratory material we have two chromatographs, one of them, SPME Arrow – GC Intuvo – MS/MS, which allows us to have full control of the sensory deviations of the batches, quickly and very efficiently, either to discard before the purchase to minimize them to undetectable levels thanks to our sensory deviation reduction systems.

In addition to the tests in our laboratory, we collaborate with wineries in order to experience our innovations in situ and thus create a closer relationship with our customers and that they can benefit from our constant work to always be at the forefront of research.

We participate in sectoral research projects or together with external laboratories, universities, and research centers, intending to permanently innovate, expanding our knowledge, and incorporating new technologies that provide added value to our clients.

We are part of the AECORK Technical Committee as well as the UNE CTN 056/SC 05 “CORK” Committee that coordinates the state regulation of the cork stopper.

Finally, we would like to highlight our commitment to rigor, quality, and the environment, as shown in our certification policy, which has always been very demanding.

Not just TCA

At J·Vigas we rely on two technologies for the detection and elimination of TCA and other unwanted aromas:

SPME Arrow Chromatography – GC Intuvo – MS/MS and Detection with Manual Sniffing.

No other technology has met our demands and tolerance levels.

Innovation Projects

Innovation Projects

Sensory deviations

Projects to reduce and eliminate unwanted odors.

Analysis of the available technologies to assess their performance.

VIEW PROJECTS ⟶

Oxygen transfer

Studies to deeply understand how oxygen is transferred once the wine is bottled. What effects it has on wine quality, and how to characterize corks based on oxygen transfer.

VIEW PROJECTS ⟶

Other topics

Various projects related to aspects such as the internal structure of the cork, the study of our carbon footprint, or hidden cork defects, among others.

VIEW PROJECTS ⟶

Sensory control

Up to six analytical control points

Sensory control

Up to six analytical control points

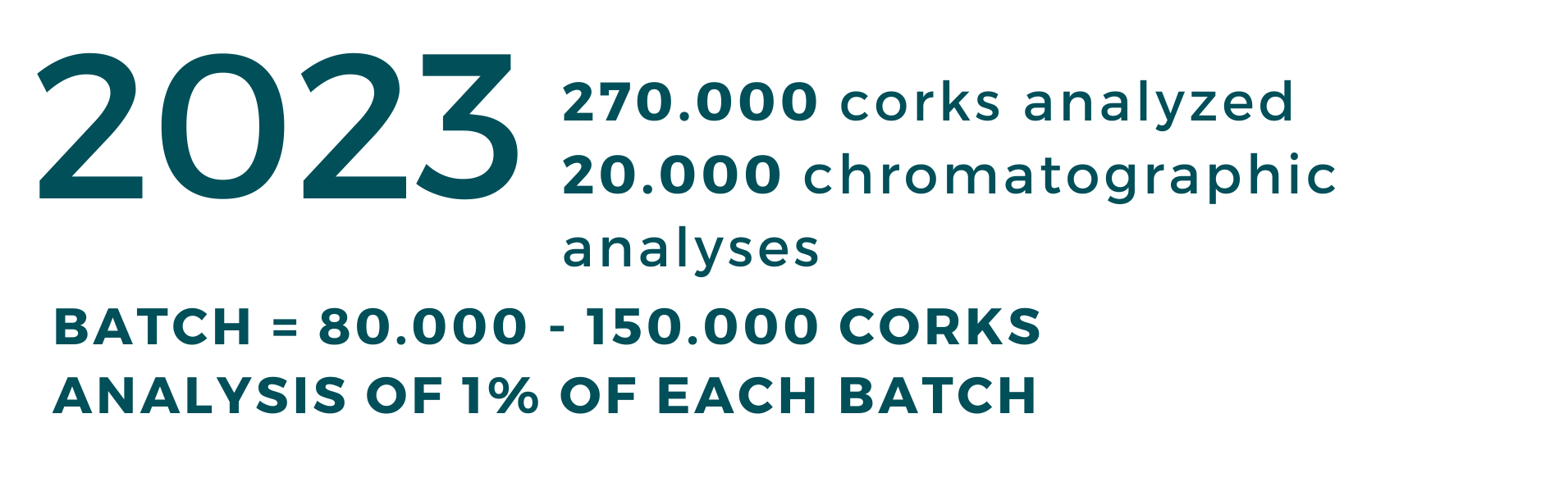

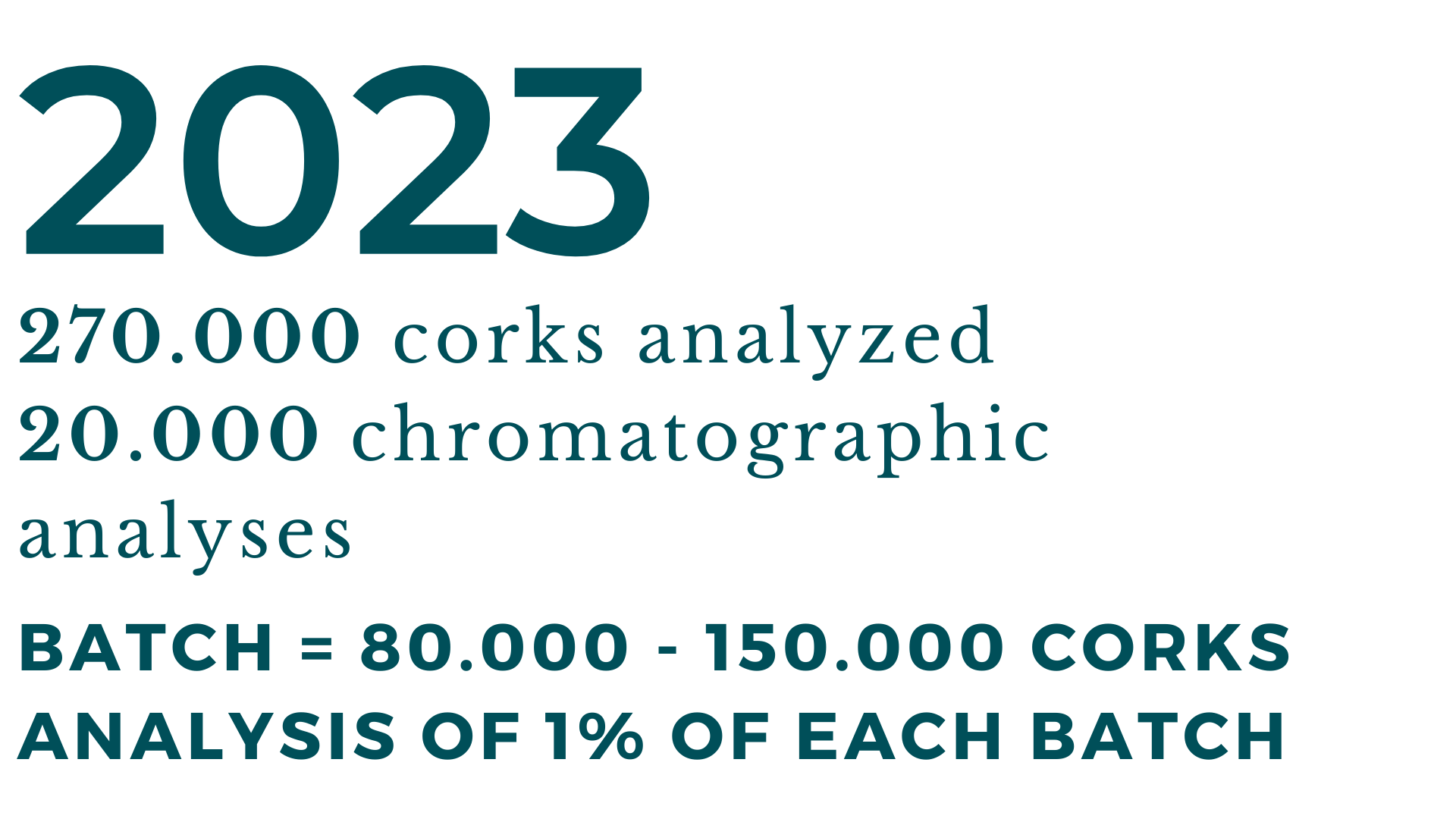

Our technical team analyzes 1% of the corks from each batch to ensure the highest quality at a sensory level. Last year we carried out a total of 20,000 chromatographic analyses, analyzing a total of 270,000 corks.